NTI Process Solutions offers 24/7 service on steel belts, with the ability to handle any repair, large or small. Utilising the latest technology and service tools to provide a professional and long lasting repair. Your damaged steel belt can be returned to service as quickly as possible, ensuring that your production schedule will not be affected.

For extra peace of mind, your NTIPS Service Engineer is certified by DEKRA ISO 14732 to weld all steel belt materials, along with being certified through IPCO’s world-class training program covering all aspects of belt repair from Grinding and Polishing, to Edge-Dressing and QuickDisc patching, plus an in-depth knowledge of all IPCO Product offerings.

NTIPS has service equipment is located strategically in both Australia and New Zealand, allowing for timely arrival, as steel belt repairs are recommended to only be attempted by trained and competent personnel, with the right tools. Some repairs can be temporarily patched to allow continued production until a shutdown period where the complete repair can be performed.

Inspections

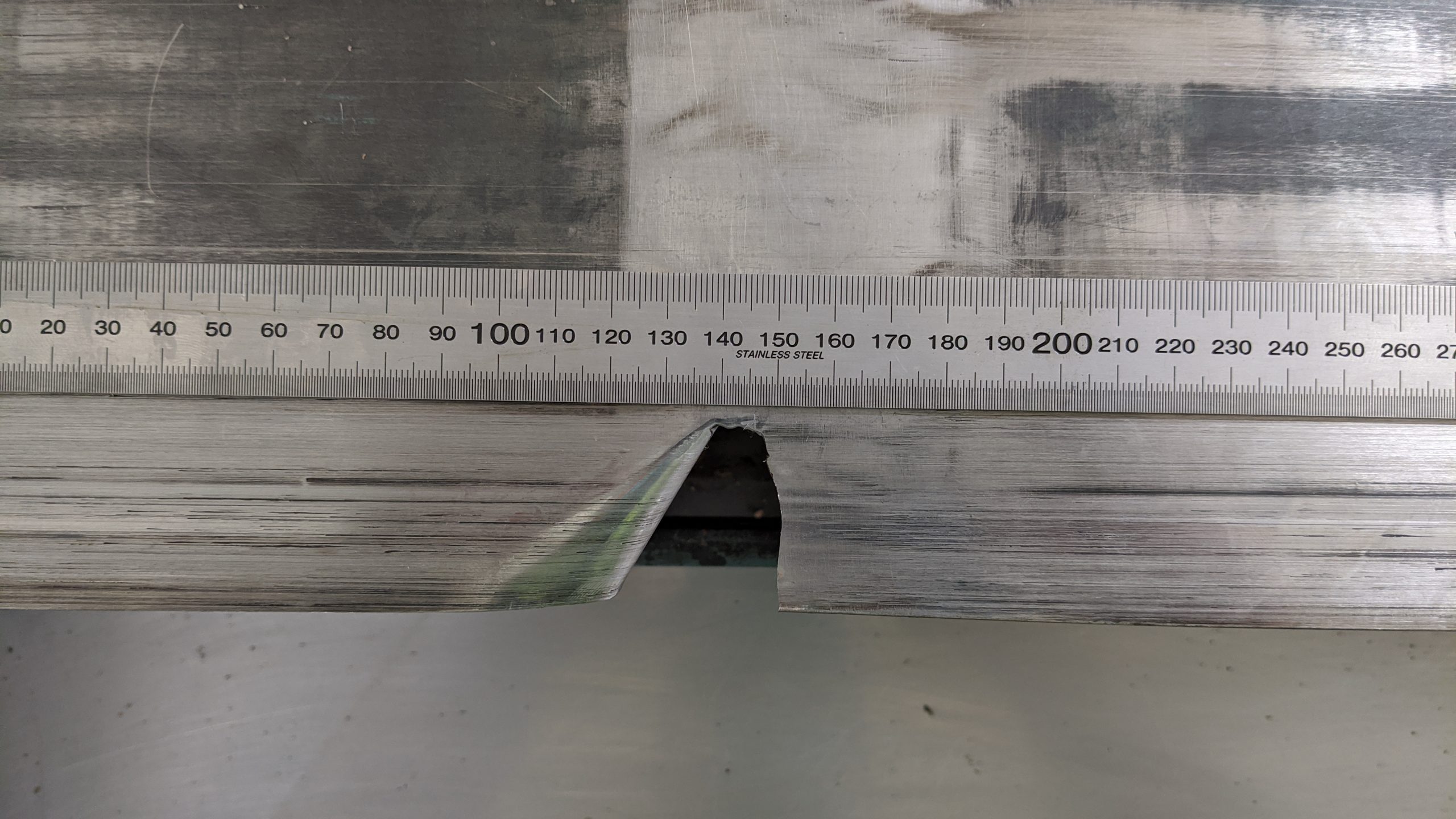

Having an NTI Process Solutions Service Engineer provide regular inspections of your steel belt and associated machinery will ensure that all potential areas of damage are found before they become a serious problem, allowing for your steel belt to maximise its lifespan, and giving you many years of trouble-free production.

Protection

Your NTIPS Service Engineer will provide a comprehensive report after each inspection, outlining any concerns and what is required to remedy these. Cracks, scratches, elongations and corrosion are all preventable yet expensive repairs.